Structured Wave Energy Equipment Test Laboratory

TA83 – UCC-VGA-VGATL

Location

Via Foscolo, 1

6053 Deruta, Italy

Description

The Structured Wave Energy Equipment Test Laboratory (SWEET lab) provides support for accelerating the development of ocean energy technologies by de-risking their key subsystems through three facilities:

- Drivetrain test rig

- Structural components test rig

- A climatic chamber

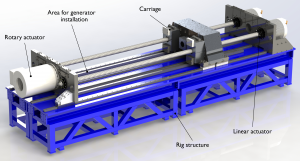

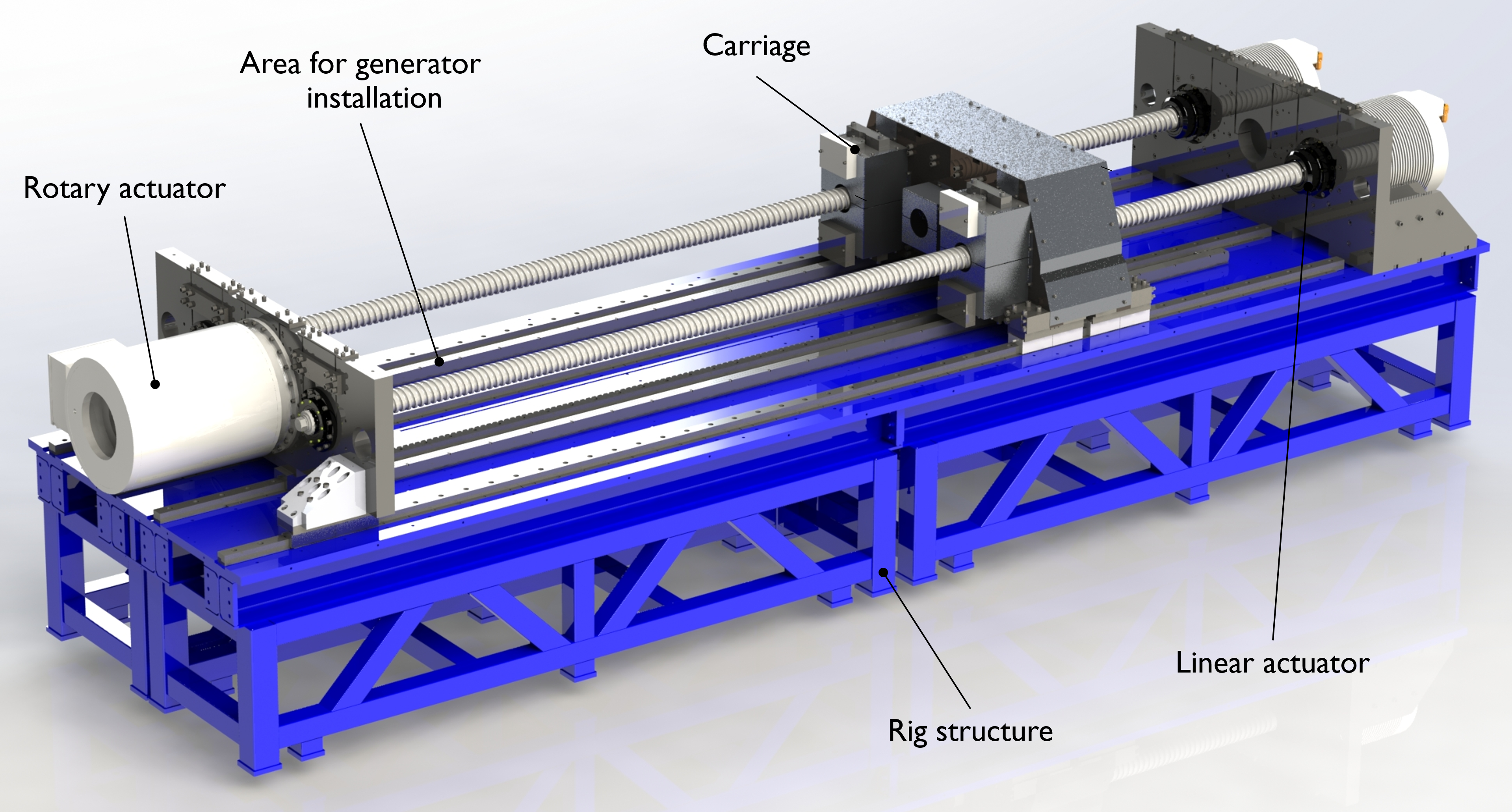

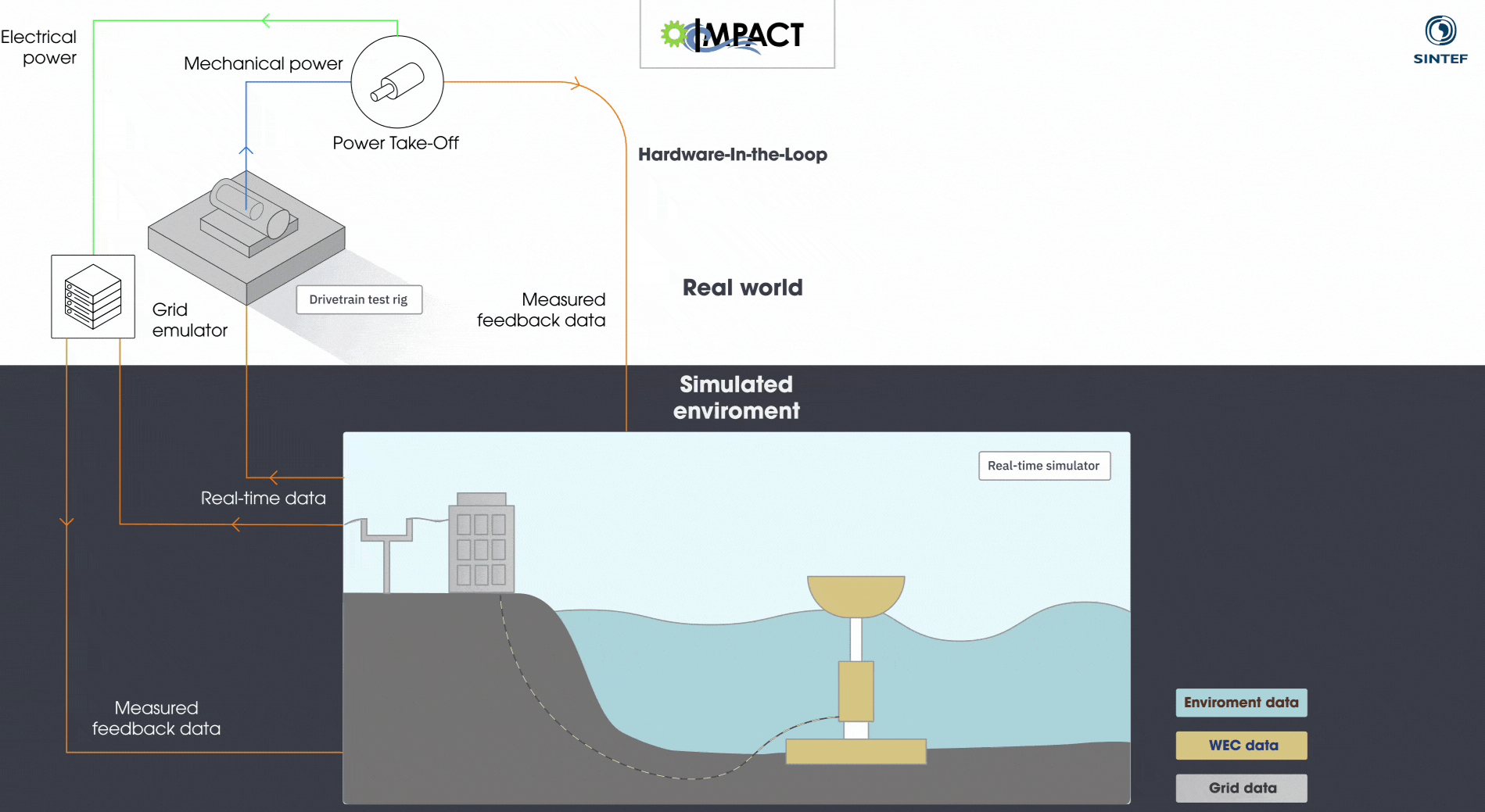

Drivetrain Test Rig

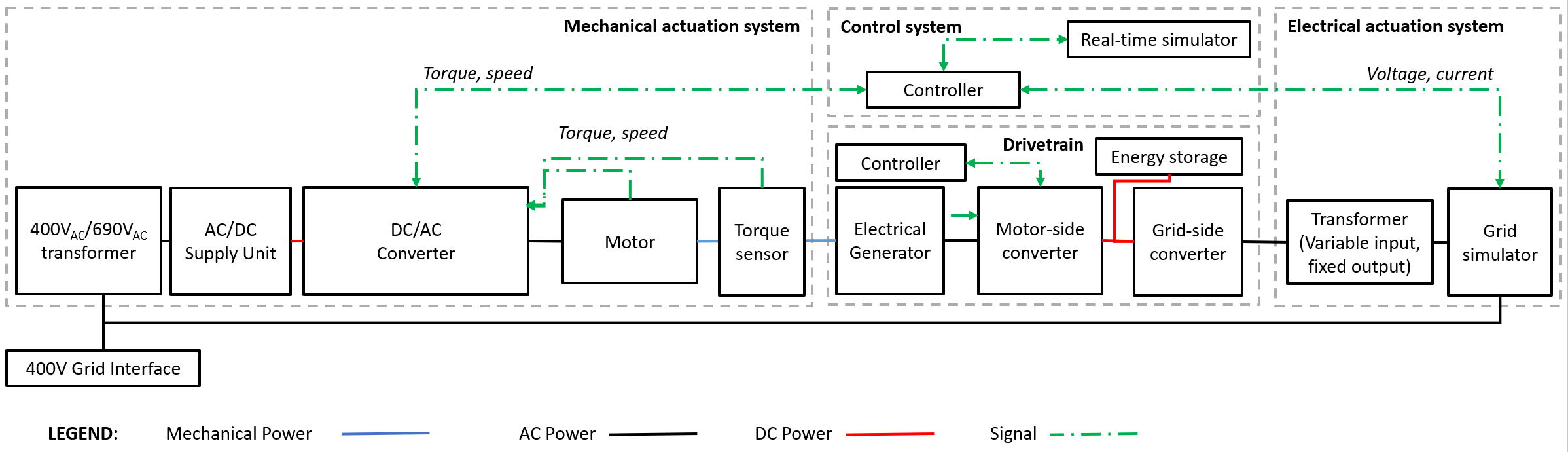

This rig targets the entire drivetrain, from the input mechanical power to the output electrical, grid-compliant power. This conversion chain includes the following subsystems:

- Mechanical drives (gearbox, ball/roller/lead screw, rack-pinion, belt-pulley)

- Electrical generators

- Power converters

- Storage systems

- Grid interface units

- The control system

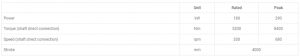

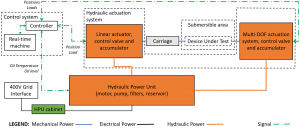

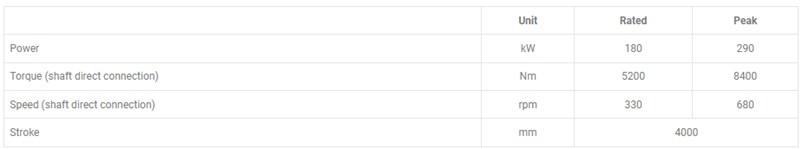

The drivetrain test rig is able to provide either linear or rotary input power with a flexible set-up. The following table provides the power limits and the initial values of rotary torque and speed. Rotary-to-rotary (e.g., gearboxes) and rotary-to-linear (e.g., ball-screws) motion conversion drives can be used to reach different load-speed ratios.

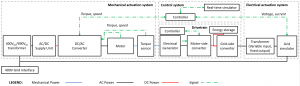

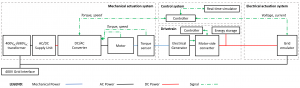

An electrical actuation system is made up of a grid simulator, while a variable-input, fixed-output transformer is able to provide different voltage levels and scenarios, according to the load case to be tested (power production, occurrence of a fault, start-up, shut-down).

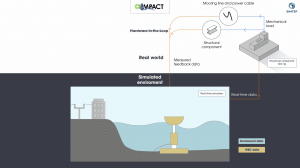

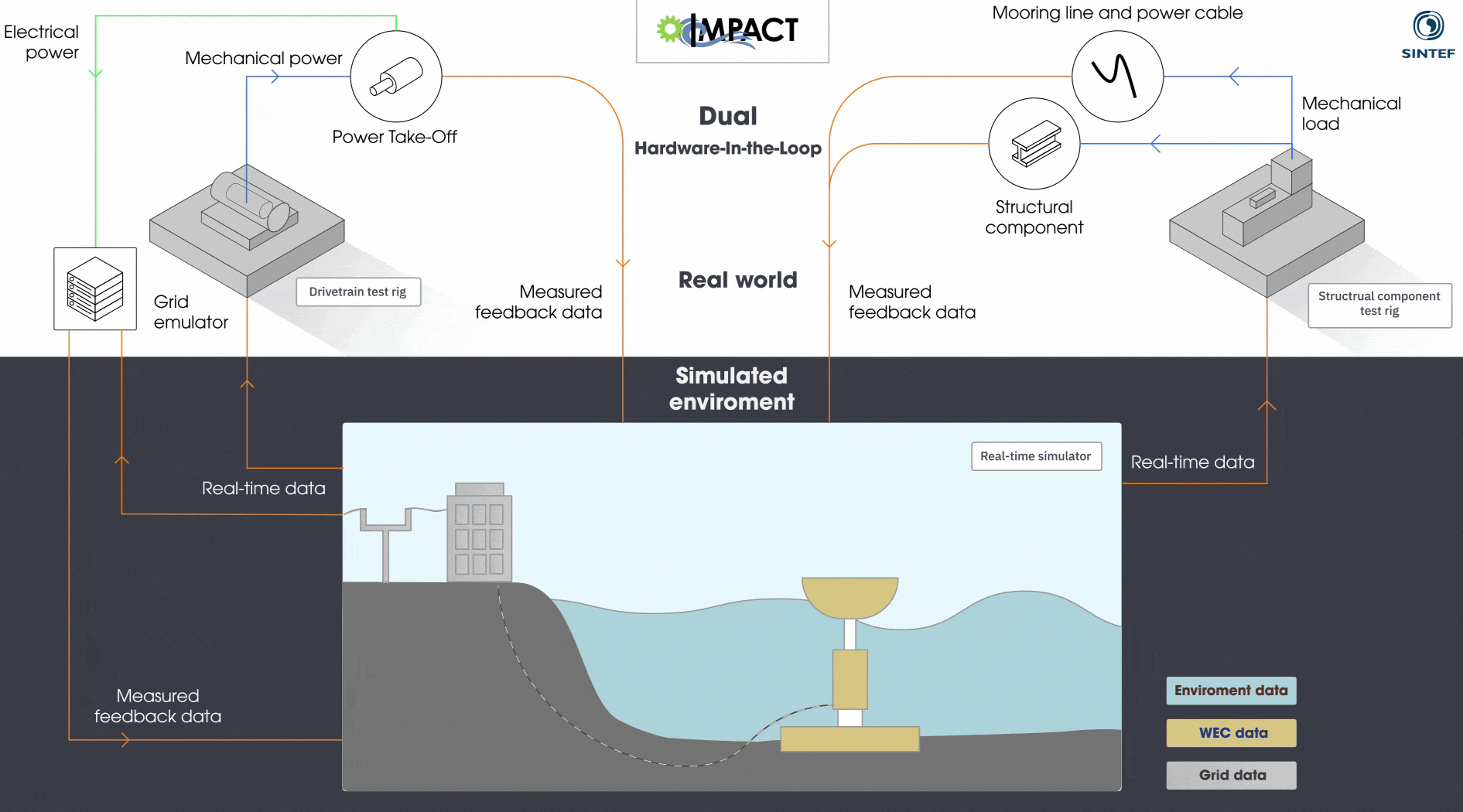

The rig controller manages both mechanical and electrical actuation systems and can also be used in a hardware-in-the-loop (HIL) setup, to emulate the interaction of the subsystem/component under test with the rest of the Wave Energy Converter (WEC).

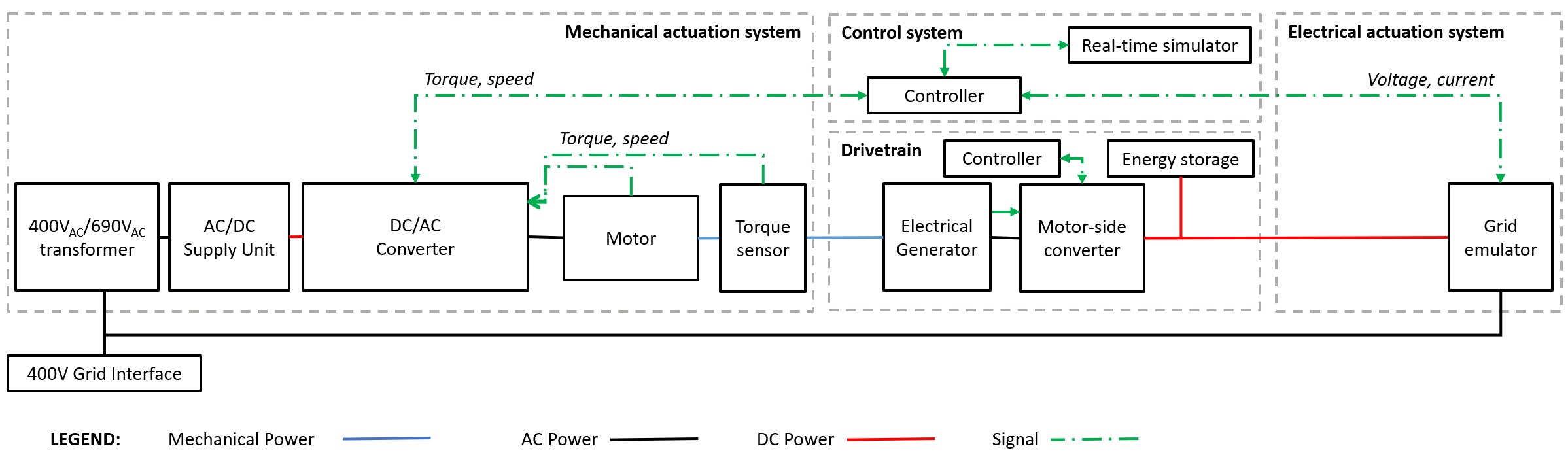

A similar approach can be adopted also for Direct Current (DC)-connected plants, as shown in the following scheme.

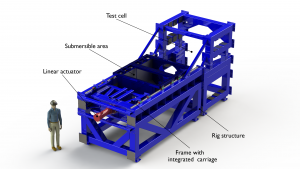

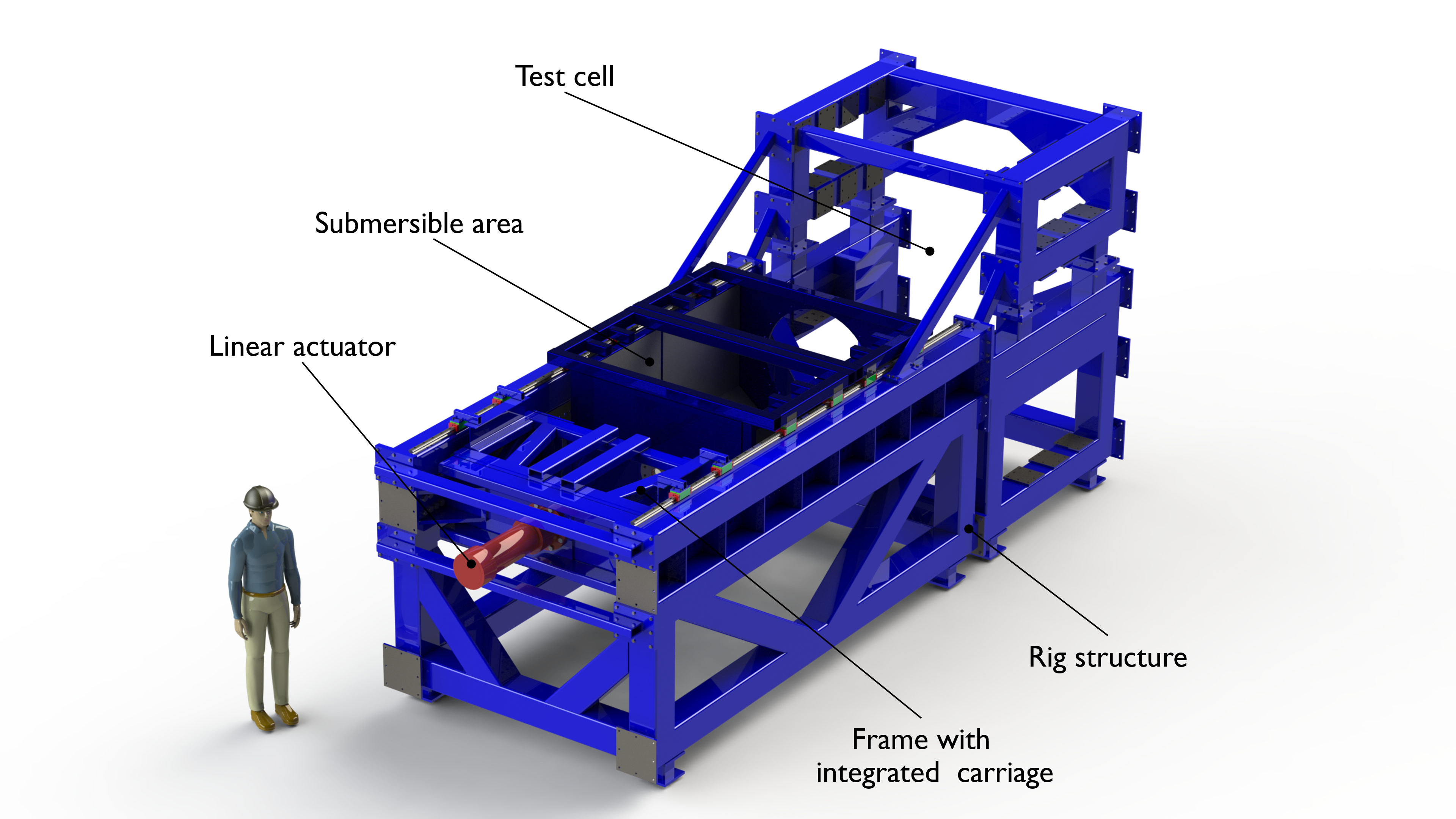

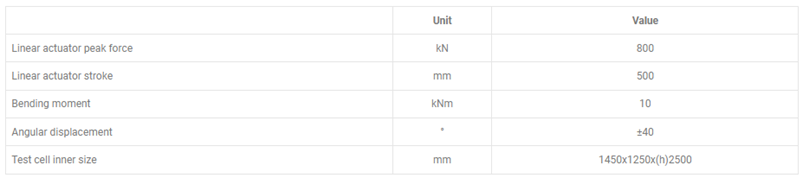

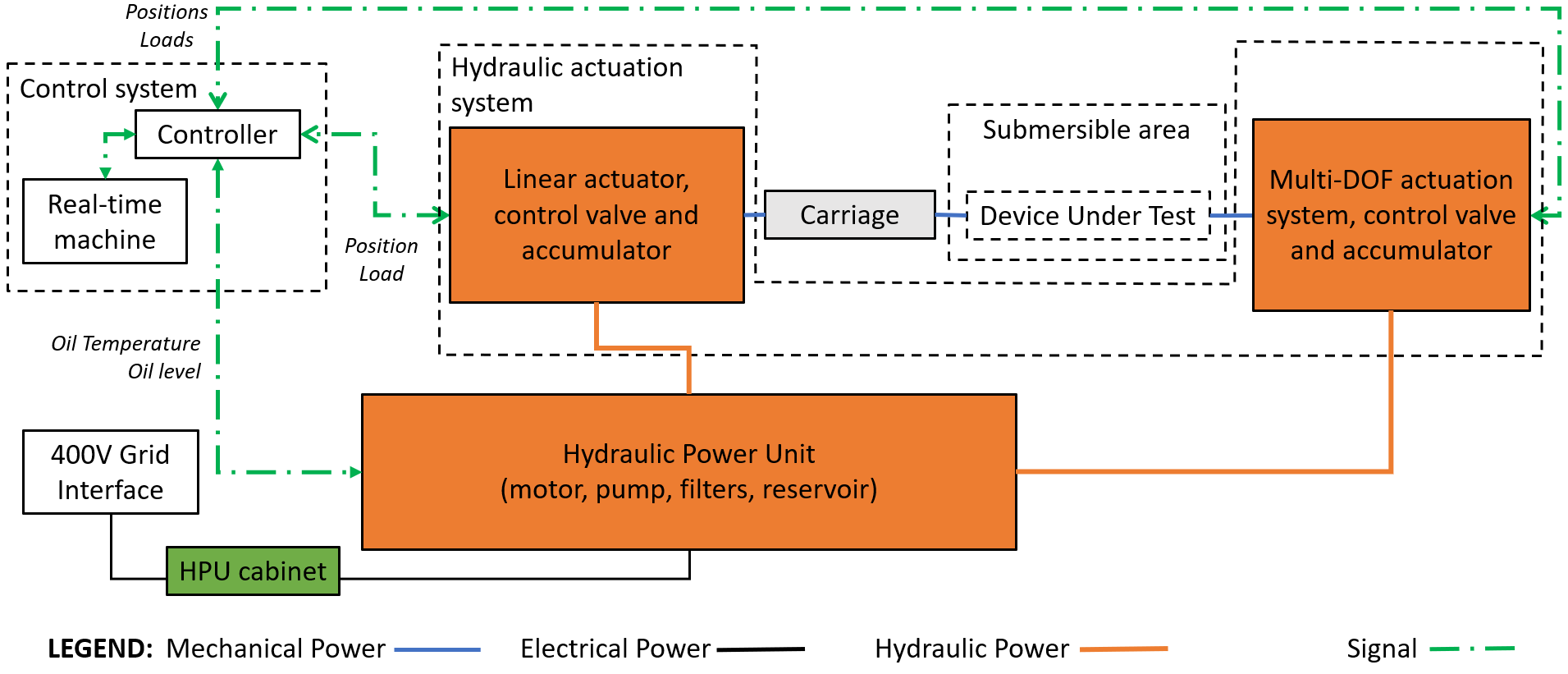

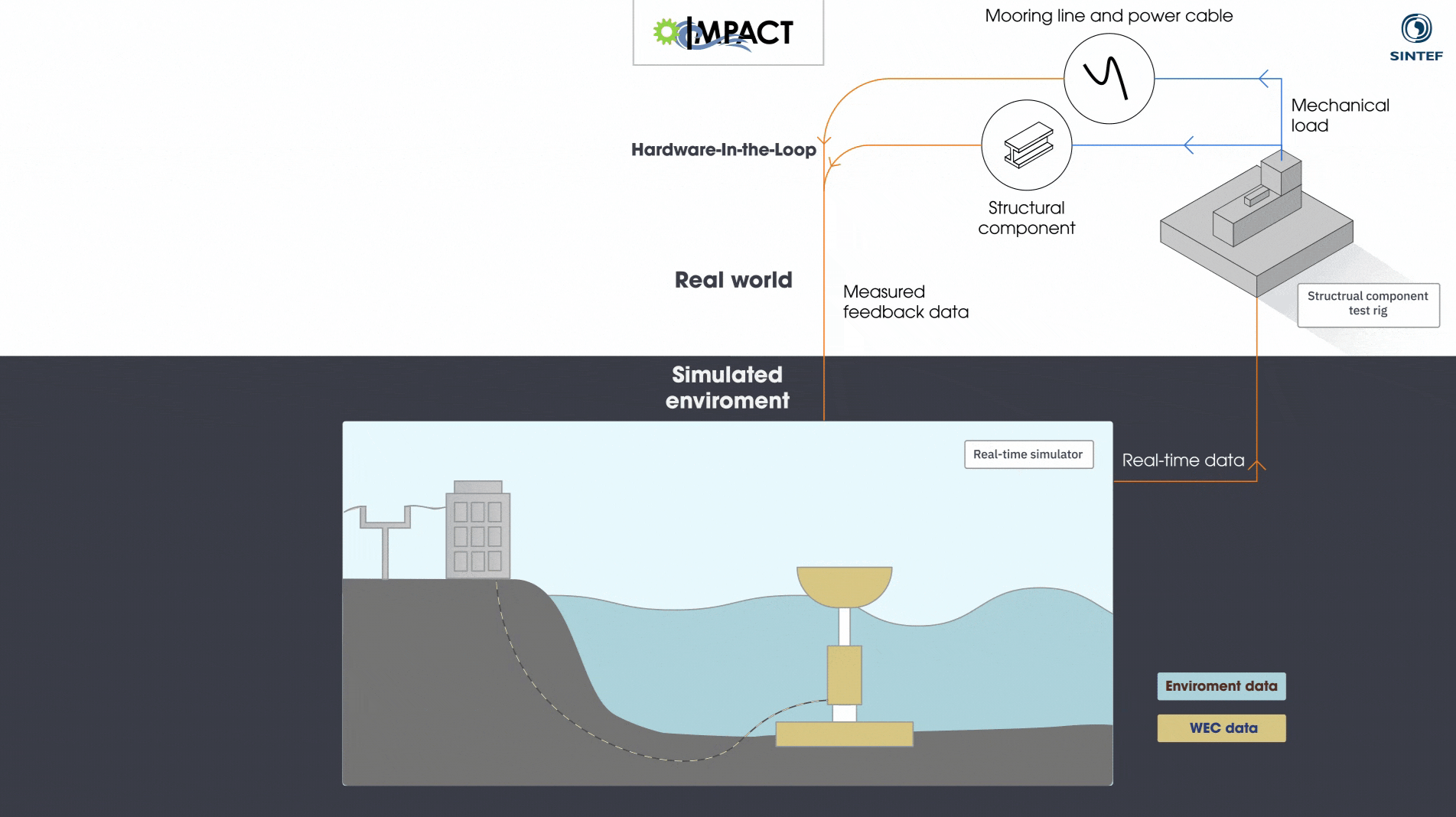

Structural Components Test Rig

This rig targets several components/subsystems of ocean energy conversion technologies:

- Structural components (as part of the hull)

- Mechanical interfaces

- Power cables

- Sealing systems

The rig can actuate one linear degree of freedom at one end and up to five degrees of freedom at the other end (three linear and two rotary). As a result of the test cell, loads, bending moments and torque can be provided by on-purpose arrangements according to the load application. Environmental conditions can be replicated by submerging the test sample in synthetic sea water (requiring a dedicated equipment).

These features allow the dynamic testing of large-scale components with realistic motions and loads, also in wet environment.

The rig can also be used in a HIL setup to emulate the interaction of the subsystem/component under test with the rest of the WEC.

Climatic Chamber

It can be used to test key components such as storage systems, controllers and power converters. A custom-made external chamber can be connected to the climatic chamber and equipped with the actuation of one axis (rotary or linear), to undertake temperature-fatigue Highly Accelerates Life Tests (HALTs).

Beside SWEET lab access, VGA offers to the users a full-package testing service, including identification of the testing and modelling techniques, definition of the test setup, risk assessment, drafting of test plan, execution of test campaign, data processing and reporting.

VGA S.r.l. is an engineering company specialised in the design, development and operation of test rigs and high-technology prototypes.

Testing Capabilities

The SWEET lab addresses two key activities within the research environment:

- Testing services for the development of ocean energy technologies, to de-risk and increase their maturity by measuring key performances indicators (efficiency, reliability and survivability). This process ensures a faster, target-oriented development path towards commercialisation.

- Research and Development (R&D) activities, fostering the collaboration between academia and industries. The SWEET lab is the “common ground” where research institutions and private companies could work together for progressing in the scientific understanding of the ocean energy in terms of its main goal: extracting energy from waves and converting it into electrical energy through a reliable, cost-effective and efficient process.

The SWEET lab makes use of the above-mentioned rigs to undertake several activities for increasing the maturity of energy technologies:

- Subsystem/component characterisation: For a basic understanding of the characteristics and functional capabilities of the Device Under Test (DUT), aspects such as the DUT mechanical properties (e.g., stiffness and damping), its efficiency (in case of Power Take-offs (PTOs)) and survivability (i.e., degree of overload the system can be subject to while not experiencing damage or loss of functionality) can be tested. These aspects are key when a device is still at early Technology Readiness levels (TRLs).

- Accelerated tests: Ocean energy devices are expected to work for twenty years in the marine environment. The SWEET lab allows to carry out qualitative (QualAT) and quantitative (QualAT) accelerated tests. QualAT aims to identify and characterise failure profiles by mapping a range of input conditions that may affect the failure phenomenon. QuanAT aims to quantify the failure time and/or degradation pattern of the DUT at typical usage levels. Accelerated tests could be used either to identify criticalities of subsystems or components in a preliminary design phase and to characterise their reliability, therefore informing the Operation and Maintenance (O&M) strategy to adopt, aiming at the device long-term durability.

- Hardware-In-the-Loop (HIL) test: HIL (also known as hybrid tests), is the state-of-the-art testing technique where the DUT is virtually connected to a simulation environment integrating the remaining part of the device and the external conditions it is subject to (e.g., waves, current and wind). Following an actuation input determined by the real-time simulation, the reaction of the DUT is measured and fed back into the real-time simulator. This technique can be used by both the drivetrain and structural components test rigs. The results lead to de-risk its development, especially prior the deployment phase, and to estimate more precisely its Levelized Cost of Energy (LCOE).

- Dual HIL test: it combines together two HIL-equipped rigs as a step beyond the state-of-the-art to find out eventual interdependencies between subsystems and increase the accuracy in the numerical modelling, allowing to deeper knowledge of the technical and economic performances of the DUT and ultimately of the WEC.

Technical Equipment

Drivetrain Test Rig

Mechanical actuation systems

- N.1 rotary actuator (Max values: T=8400Nm, w=680rpm)

- N.1 linear actuator (Max values: F=150kN, v=1m/s, stroke=4000mm)

- N.1 low-power rotary actuator (Max values: T=130Nm, w=1150rpm)

Electrical actuation system

- N.3 AC interfaces (Max. values: 165kW at a voltage up to 1200Vrms)

- N.1 DC interface (Max. values: 110kW at 990V or 165kW at 495V)

Signal interfaces and transducers

- N.1 10kNm torque meter

- N.1 200kN load cell

- N.2 4240mm linear encoders

- N.1 10kNm torque meter

- N.1 10krpm encoder

- N.4 current transducers (1000Arms or Adc)

- N.4 voltage transducers (1000Vrms)

- N.32 single-ended analog channels or N.16 differential 16-bit inputs (±10V max)

- N.1 real-time system with N.12 digital, N.3 analog and N.1 EtherCAT slave output interfaces

- N.4 interfaces for voltage, bridge, resistance and RTD measurement (±10V max)

- N.16 digital I/Os

- N.4 16-bit analog outputs (±10V max)

- N.1 thermal gauge for DUT temperature inspection

- N.1 additional thermal gauge interface (PT100)

Ancillaries

- Water cooling system available (27lpm, 8bar)

Structural Components Test Rig

Test cell inner size: 1.45x1.25x(h)2.5m

Linear actuation systems

- N.1 high-load hydraulic actuator (Max. values: F=800kN, v=0.1m/s, Stroke=0.5m, f=0.15Hz with 100mm displacement, f=10Hz with 1mm displacement, equipped with position sensor)

- N.1 high-speed hydraulic actuator, long stroke (Max. values: F=44kN, v=0.5m/s, stroke=0.8m, equipped with position sensor)

- N.1 high-speed hydraulic actuator, medium stroke (Max. values: F=44kN, v=0.5m/s, stroke=0.6m, equipped with position sensor)

- N.1 high-speed linear electro-mechanical actuation system, short stroke (Fmax=56kN, vmax=0.8m/s stroke=0.2m)

Rotary actuation systems

- N.1 rotary servo actuator (Max. values: T=320Nm, w=250rpm)

- N.1 2-DOFs gimbal system (Max. values: T=20kNm, w=60rpm, Angle=±40°)

Signal interfaces and transducers

- N.32 single-ended 16-bit analog input channels (±10V max)

- N.1 real-time system with N.12 digital, N.3 analog and N.1 EtherCAT slave output interfaces

- N.1 1000kN load cell

- N.1 56kN load cell

- N.1 300mm encoder

- N.2 thermal gauges for DUT temperature inspection

Climatic Chamber

- Temperature range: from -70°C to +180°C

- Inner size of integrated chamber: 0.7x0.85x(h)0.85m

- Inner size of external chamber: 0.85x0.65x(h)0.43m

- Rotary actuator (within the external chamber), max values: T=10Nm, w=600rpm

Signal interfaces and transducers

- 10Nm torque meter

- N.2 external thermal gauges for external chamber intake temperature inspection

Additional information

Technology Readiness Level: 4-6

Special considerations: Health, Safety and Environment (HSE) training from VGA rig operators is required for personnel accessing the facility. Non-disclosure agreement (NDA), insurance and health certificates may be required, depending on the type of test and on the role of accessing personnel during tests.

Technology clusters: Energy Storage, Integrated Grids, Ocean Energy

Website: https://vga-srl.webflow.io/news-post/discover-sweet-lab

Availability: All year

Provision of tools to prepare data sets in a FAIR way: No