LNEG-BBRI – Unit for Bioprocessing Agro-industrial Wastes and Wastewaters

TA71 – LNEG-BBRI5

Location

Estrada do Paço do Lumiar, 22

1649-038 Lisboa, Portugal

Description

TA71 is the Research Infrastructure (RI) offered at LNEG (called BBRI-Biomass and Bioenergy Research Infrastructure) belonging to the Portuguese Roadmap of Research Infrastructures[1]. The main aim of TA71 LNEG-BBRI is the development of biomass processing technologies for different end-uses (energy-based and bio-based products), the promotion of research excellence, external services provider, and training of new professionals on sustainable bioenergy and bioeconomy.

TA71-BBRI5 is offering R&D and advanced training activities on agro-industrial wastes and wastewaters bioprocessing to the scientific community, professionals, universities, R&D institutes and industry. The activities will be directed towards professionals working in the Biomass and Bioenergy markets and MSc, PhD and Post-Doc students aiming at increasing the number of expert professionals on valorisation of agro-industrial wastes and wastewaters for bioenergy and bio-based products.

[1] https://arquivo.pt/wayback/20240119151303mp_/https://former.fct.pt/media/docs/Portuguese_Roadmap_Infrastructures2020.pdf

Testing Capabilities

Development of bioconversion processes for the valorization of agro-industrial wastes and wastewaters. Upgrading of agro-industrial wastes as secondary raw materials. Detoxification of wastewaters for fertirrigation use. Assessment of the energy potential of biomass.

Technical Equipment

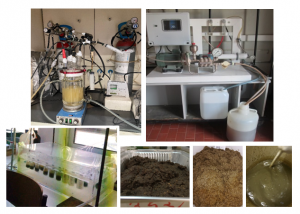

Full range equipment for processing agro-industrial wastes and wastewaters to produce energy- and bio-based products:

- The equipment for anaerobic treatment (fermentation, digestion) of agro-industrial biowastes and wastewaters includes bench scale reactors, shake-flasks for microbial culture, and anaerobic glass reactors, with the possibility of operating in non-sterile or sterile conditions. Bench-scale (1-3 L) anaerobic fermenters, including all the accessories for monitoring and control, and a workstation for isolation of anaerobic microorganisms.

- Analytical facilities include support the characterization of biomass and products, chemical oxygen demand, total and volatile solids, total nitrogen and ammonia, and volatile fatty acids (VFA) quantification, biogas monitoring, and GC systems (equipped with FID and TCD detectors) and HPLC systems (equipped with DAD- and RI detectors).

- Possibility of connecting a downstream separation stage for product concentration or separation. Several (bench and pilot-scale) membrane separation systems for downstream processing: microfiltration, ultrafiltration, nanofiltration, reverse osmosis and pervaporation.

Additional information

Technology Readiness Level: 1-3

Special considerations: N/A

Technology clusters: Biofuels, Others

Website: https://www.lneg.pt/infrastructure/bbri-biomass-and-bioenergy-research-infrastructure/

Availability: All the year

Provision of tools to prepare data sets in a FAIR way: Yes