LNEG-BBRI1 – Biomass Deconstruction Facility

TA71 – LNEG-BBRI1

Location

Estrada do Paço do Lumiar 22

1649-038 Lisboa, Portugal

Description

TA71 is the biomass deconstruction facility (sugar platform) of the BBRI-Biomass and Bioenergy Research Infrastructure offered by LNEG, which is a recognized relevant Portuguese Research Infrastructure (https://arquivo.pt/wayback/20240119151303mp_/https://former.fct.pt/media/docs/Portuguese_Roadmap_Infrastructures2020.pdf). The main aim of TA71 LNEG-BBRI is to support the development of biomass processing technologies for different end-uses (energy-based and bio-based products), promote research excellence, train new professionals on sustainable bioenergy and bioeconomy, and providing external services.

Specifically, TA71-BBRI1 supports R&D and advanced training activities on pre-treatment processes for bioproducts and advanced biofuels production to the scientific community, professionals, universities, R&D institutes, and industry. The activities will be directed towards professionals working in the Biorefineries and Bioeconomy area including graduate, MSc, and PhD students as well as Post-Docs and professionals aiming at increasing the number Biorefinery and Bioeconomy experts.

Testing Capabilities

Biomass pre-treatment/ fractionation of different types of biomasses, including forest, agriculture, agro-food residues and wastes, macro- and microalgae.

Extraction of different classes of bioproducts and added-value compounds, e.g., essential oils, phenolic extracts, hemicellulose-derived products (oligosaccharides, monosaccharides), lignin-derived products, and cellulose-rich solids.

Preparation of hydrolysates for culture media purposes.

Downstream processing using membranes at lab-, and pilot scale.

Technical Equipment

The biomass fractionation processes development unit contains a full range of biomass process equipment from biomass preparation to deconstruction/fractionation and biofuels and bioproducts purification systems.

Biomass preparation equipment includes comminution, drying, pelletizing, washing, and impregnation equipment.

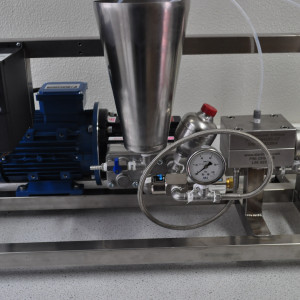

The biomass deconstruction/fractionation installation has several stainless-steel lab-scale stirred batch reactors - 160 mL (max. 200 bar, 350°C), 250 mL (max. 300 bar, 500°C), 600 mL (max. 125 bar, 350°C) and 2 L (max 125 bar, 350°C) - heated by external fabric mantles/heaters; and with precise PID temperature and agitation control. A continuous extruder-type reactor (1 kg/h, 250 ºC, and 50 bar) is also available. This installation can carry out all types of fractionation processes, including, hydrothermal, dilute acid, organosolv, alkali, CO2, ionic liquids, inorganic salts, and solid super acids-assisted processes. A 50 L direct steam stainless steel batch reactor is also available for biomass pre-treatment. Lab and pilot scale extraction reactors are also available from 1 L to 500 L.

Separation and purification equipment include lab- and pilot micro-, ultra-, and nanofiltration and reverse osmosis membrane systems that can operate up to 400 L/h. A preparative chromatographic system (size-exclusion and ion-exchange chromatography) is also available.

Chemical analyses of biomass and products are supported via UPLC-MS, HPLC systems (equipped with PAD-, DAD-, UV-VIS-DAD, and RI-DAD detectors), and Capillary Zone Electrophoresis.

Additional information

Technology Readiness Level: 4-6

Special considerations: N/A

Technology clusters: Biofuels, Hydrogen, Materials for Energy, Others

Website: https://www.lneg.pt/en/infrastructure/bbri-biomass-and-bioenergy-research-infrastructure-2/

Availability: All the year

Provision of tools to prepare data sets in a FAIR way: Yes