DLR-TFCL

TA67 – DLR-TFCL

Location

Carl-von-Ossietzky-Str. 15

26129 Oldenburg, Germany

Description

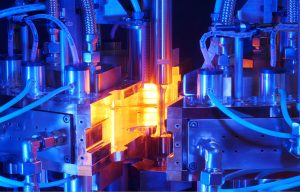

The DLR coating laboratory is a large facility at the Institute of Solar Research, which serves as a modular R&D production line for the manufacturing of novel thin film technologies. The primary goal is the system and material innovation in energy conversion, novel Photovoltaic applications, radiative cooling, H2 technologies and concentrating solar power. The laboratory is used for the development and analysis of coatings and functional surfaces and their integration into prototype devices like PV windows, Photo Electrochemical cells, Fuel Cells and highly efficient and durable mirrors for Concentrated Solar Power (CSP) Heliostats.

The laboratory is equipped with a variety of coating tools, front-end and back-end systems as well as numerous characterisation methods for the manufacturing of thin-film technologies. For the reliable and reproducible production also of high TRL prototypes, the laboratory infrastructure is near to industrial level. It features different state-of-the-art coating machines for implementing manufacturing processes that can easily be transferred to industry partners for mass production.

Description of the infrastructure:

This combination of inline systems for developing processes and prototypes at near-industrial scale is designed for a substrate size up to 30x30 cm2. It includes the following systems:

- An industrial glass cleaning system

- A magnetron sputtering system for deposition of Transparent Conductive Oxides (TCO), metals, metal-nitrides, oxides and oxynitrides using pulsed DC, RF, HiPIMS and Bipolar-MF processes on planar and rotatable targets

- A lamination unit and an ultrasonic soldering station for bonding as well as contacting coated substrates for prototyping.

In addition to the described Research and Development (R&D) manufacturing line, the Institute also has a well-equipped characterisation laboratory. This supports numerous characterisation methods for the manufactured thin-film technology demonstrators, such as a combined Scanning Electron Microscopy (SEM) and Focus Ion Beam (FIB) system, a Hall sensor, various spectrometers (e.g., UV-VIS-NIR, Raman, FTIR), plus a wide range of electrical and optical measurement methods.

Support offered under this proposal:

In addition to the supply of an up and running technical infrastructure described above, technical and logistic support for preparing, developing, manufacturing, and characterisation samples can be offered to the users. The scientific and technical staff is well-trained and has experience from several national and international R&D projects with industry and research partners.

Testing Capabilities

It offers services for developing and manufacturing novel thin film technologies, including coatings for PV windows, photoelectrochemical cells, and CSP heliostats. The facility provides support for the production of high Technology Readiness Level (TRL) prototypes, including coating and characterisation methods, with near-industrial scale equipment and expert technical support.

Technical Equipment

An industrial glass cleaning system, magnetron sputtering system for TCOs, metals, and oxides, lamination unit, ultrasonic soldering station, PVD system, Langmuir-Blodgett coater, SEM-FIB system, Hall sensor, and various spectrometers (UV-VIS-NIR, Raman, FTIR).

Additional information

Technology Readiness Level: 7 or above

Special considerations: N/A

Technology clusters: CSP/STE, Hydrogen, Materials for Energy, PV

Availability: All year

Provision of tools to prepare data sets in a FAIR way: Yes