Jülich Living Lab Energy Campus

TA74 – FZJ-LLEC

Location

Wilhelm-Johnen-Straße

52428 Jülich, Germany

Description

Jülich’s Living Lab Energy Campus includes a comprehensive instrumentation of selected buildings, the integration of demonstrator units for energy conversion and storage, and a data and energy services lab as the research hub of Living Lab to collect and process the data required to fulfil the research tasks. It is a research infrastructure for real-time analysis and operational optimisation of decentralised energy systems. The scientific objective is the development of modelling tools to provide a planning process for an integrated forecasting approach based on a dynamic analysis of all energy streams. The smart energy management system is based on the latest Future Internet (FI) technologies supported by the European Commission in the form of different software packages made available by the open innovation platform Future Internet Lab (FIWARE LAB) applications. The campus of Forschungszentrum Jülich is the first large-scale field trial of this advanced FI technology in Germany. All devices are equipped with metres and power quality analysers. The innovative energy demonstrators (e.g. H2 related conversion and storage units) are scientifically equipped with dedicated sensors. For the application and testing of control systems for district energy systems, all devices will be connected to the information and communication technology (ICT) platform after deployment.

Testing Capabilities

- Photovoltaic (PV) testbed for module characterisation and aging (in operation):

- Several PV installations are highly instrumented to test different physics properties. A PV module monitoring system, PV roof and open field installations allow for testing different module technologies, applications, and reliability issues on PV module as well as on PV system level. AI-based software tools are being developed for early failure detection in a PV system and for optimising performance prediction for integrated PV such as BIPV, road integrated PV or vehicle integrated PV.

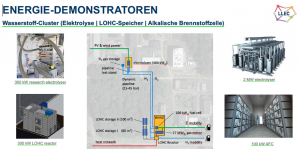

- High efficiency 400 kW electrolyser:

- A key component of the 400 kW electrolyser is a PEM Fuel Cell Stack which was newly developed at IEK-14. A new one piece bipolar plate will be used together with 50 µm thin membranes to fulfil both, high performance and low costs.

- The 75-cell stack will be operated in a greenlight test rig. Operating conditions for the stack are flexible between 2-50 barg, 40-90 °C, 0-4000ADC and 0-125 VDC. Hydrogen production is possible with up to 9 kg/h.

- Alkaline fuel cell (100 kW):

- The alkaline fuel cell consists of three systems in total. Two air-cooled 30 kW systems and one 60 kW liquid cooled system. In contrast to the classical alkaline fuel cells, these systems do not need a liquid electrolyte. Due to the different system sizes and cooling systems, the optimal combination in regard of system efficiency and lifetime can be investigated.

Technical Equipment

- ICT platform for building and district energy systems:

- The open-source cloud platform FIWARE with a collaborative and mature ecosystem of developers, innovation hubs, accelerators, cities and more than 1000 SMEs and startups is used as a basis for our ICT platform.

- Flexible integration and provisioning of further energy generation, conversion, and storage (ontologies for typical units available).

- Well defined API for the application of innovative monitoring and control approaches.

- LTDH network with HPC waste heat integration:

- Testbed for the application and demonstration of advanced (cloud-based) controllers for low-temperature district heating LTDH. Algorithms can, for instance, provide setup points for the multiple heat pumps and heat storages in the buildings connected via cAPI.

- Backup operation modes and safety modes (e.g. watchdogs, toggle bits, ...).

- Back-up to district heating network to maintain a high level of security of supply.

- Sensors and actuators on room level in real-world buildings:

- Various buildings of different construction years and usage types to monitor and test control approaches with high statistics.

- Detailed insights in indoor air quality (IAQ) and comfort parameters on room level.

- User behaviour and interaction of users with, for instance, advanced (model predictive) control via well-defined API (e.g. for valve positions, venetian blinds and lighting).

- Web application UI to access data and provide user preferences for room controllers.

- Climate neutral office building (ready in Q3/2025):

- All rooms will be equipped with IAQ, window and door state sensors. Additionally, larger rooms with person counters etc., and an innovative ventilation system.

- A unique feature of the climate-neutral office building is that different parts of the buildings can be ran using different control modes at the same time. This allows for a 1 to 1 comparison of different control algorithms.

- High energy and high-power batteries:

- The high energy battery is the first of its kind (in Germany) and provides a capacity of up to 2.7 MWh. Data up to the cell level is available to examine optimised battery charging and battery aging processes.

- LOHC reactor and storage system:

- The LOHC one reactor is also a FOAK system (worldwide) at the given scale allowing for storing and releasing hydrogen chemically bound to the LOHC system benzyltoluene/perhydro-benzyltoluene in one reactor. Today, only lab scale systems with a few Kilowatts are The system has a power of 300 kW and is coupled to the CHP plant to make use of exhaust heat of about 330°C.

Additional information

Technology Readiness Level: 4-6

Special considerations: N/A

Technology clusters: Energy Storage, Hydrogen, Information and Communication Technologies, Integrated Grids, PV

Website: https://www.fz-juelich.de/en

Availability: Various availability timelines

Provision of tools to prepare data sets in a FAIR way: Yes