FASTinMat

TA16 – CEA-FASTinMat

Location

CEA Saclay

91191 Gif sur Yvette, France

Description

FastInMat infrastructure enables the synthesis of nanoparticles as dry powders or colloidal suspensions by gas- or liquid-phase processes, as well as the safe deposition (both process and product safety) of these particles to obtain nanostructured films, coatings and composites. Owing to the very wide range of nanomaterials that can be prepared, most energy-related research domains can take advantage of this facility. Depending on the targeted material or application, user scientists can choose the most efficient synthesis process, gas or liquid, which are both available at the same location.

In addition to most of the conventional techniques, FastInMat offers rare ageing and characterisation opportunities for nanostructured or conventional materials, and in some cases under operando conditions (NMR, SAXS, nuclear microprobe, electron beam ageing (radiolysis)).

Testing Capabilities

FastInMat offers users the possibility to synthesise advanced nanomaterials on demand with a wide range of achievable structures and a reduced development time owing to real-time characterisation. Obtained materials can then be further investigated with available characterisation techniques on the facility or in users’ lab for their concerned energy application.

FastInMat takes advantage of its location within the CEA research centre at the heart of the Université Paris-Saclay’s research cluster. Strengthened by many collaborations within the university, FastInMat provides users with a top-level research environment and possible collaborations regardless of the investigated energy field.

Using the nuclear microprobe, it is possible to quantitatively measure light elements such as hydrogen in metallic matrices (like nuclear fuel claddings) to map elemental distributions of intercalation elements such as Li within graphite layers, and to probe and quantify light element distributions in carboxide compound interfaces. These quantitative results are obtained thanks to the well-known physics underlying the interaction of ion beams with materials.

After irradiation with ALIENOR, aging generated very quickly in the samples can be characterised through identification of the formed gaseous products and by using electrochemistry and various spectroscopic techniques.

The acquisition of NMR data is supported by senior researchers with strong expertise in the development of NMR methodologies for materials and flow NMR, NMR theory and computational (MD/NMR) approaches.

Technical Equipment

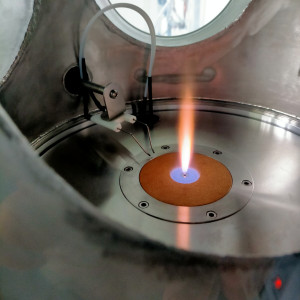

- Flame Spray Pyrolysis (FSP) reactorfor gas phase synthesis of dry nanopowders (mainly oxides but some non-oxides are possible too). Open since January 2023, this setup enables the production of simple oxide particles such as SiO2 but also more complex structures such as doped particles, multi-element phases (perovskites, nasicon…), core-shell or hollow particles, and composites.

- The liquid phase reactorenables the synthesis of a wide range of nanomaterials using standard chemistry glassware at up to 250 °C and ambient pressure. Reactions can be modified or fed using syringe pumps for reagent injection and the reaction progress can be monitored using a custom small-angle X-ray scattering (SAXS) platform. This platform can provide real-time metrological (in absolute scattering units) data such as particle size, polydispersity, and concentration throughout the synthesis process (SiO2 nanoparticles, metal-organic framework (MOF) nanocrystals, aluminosilicate nanotubes...). SAXS analysis will also be complemented in 2025 by in situ Raman and UV-Vis spectroscopy. Additionally, liquid-handling robots are available to produce and analyse a large number of sample (100s) autonomously with minimal user intervention. Continuous flow microfluidic reactors will also be implemented in 2025 to enable the study of solvo- and hydro-thermal syntheses at high temperatures and pressures (up to ~500 °C and ~200 bar).

- Co-deposition reactorusing nanoparticles suspensions to deposit simultaneously the particles by means of an aerodynamic lens and a matrix by PVD to obtain a homogeneous composite layer or multilayers on a 1-inch surface area. In 2024, the FSP reactor will be coupled to a mobile co-deposition unit to deposit nanocomposite layers with particles directly extracted from the flame. LIBS technique will also be implemented both on FSP and the co-deposition reactor in order to study in situ the elemental composition of the growing particles or films (2025).

- The nuclear microprobe facilityallows non-destructive chemical analysis at the micrometric lateral scale and nanometric depth scale of solid materials, with an emphasis on light elements. It uses combination of Ion Beam Analysis techniques performed using a focused energetic ion beam. The main investigated scientific topics relate to material science (materials for energy, corrosion) and earth and planetary science. Recent developments allow automated data analysis opening the way to high throughput screening experiments.

- Electron linear accelerator - ALIENORenables transferring energy to the sample, and hence, accelerating aging phenomena in order to characterise them. Aging induced by irradiation may then be analysed through gas production measurements (micro gas chromatography…), various spectroscopic techniques, electrochemistry, etc.

- Solid State NMR spectrometer(11.7T, 500WB; 7T, 300WB) equipped in high-resolution MAS NMR probe-heads, Broadband Variable-Temperature NMR. Super-wide bore imager (7T, 65 mm id) with commercial and home-built probeheads. Liquid state NMR spectrometers (11.7 T, 500NB) equipped with home-built devices for flow NMR and miniaturised liquid-state and gas-state NMR. In particular, a newly-developed 3D printed NMR insert enables the operando monitoring of redox-flow batteries and other electrochemical cells.

Additional information

Technology Readiness Level: 1-3

Special considerations: N/A

Technology clusters: CSP/STE, Energy Storage, Hydrogen, Materials for Energy, PV

Website: https://iramis.cea.fr/en/nimbe/

Availability: All year

Provision of tools to prepare data sets in a FAIR way: Yes